This BBQ awning is massive and took up most of the shop while being constructed. Its made of 1-1/4 inch steel tubing and was black powder coated when complete. Once mounted to the BBQ, a custom red fabric cover was manufactured and installed by Stark Manufacturing Company here in San Diego.

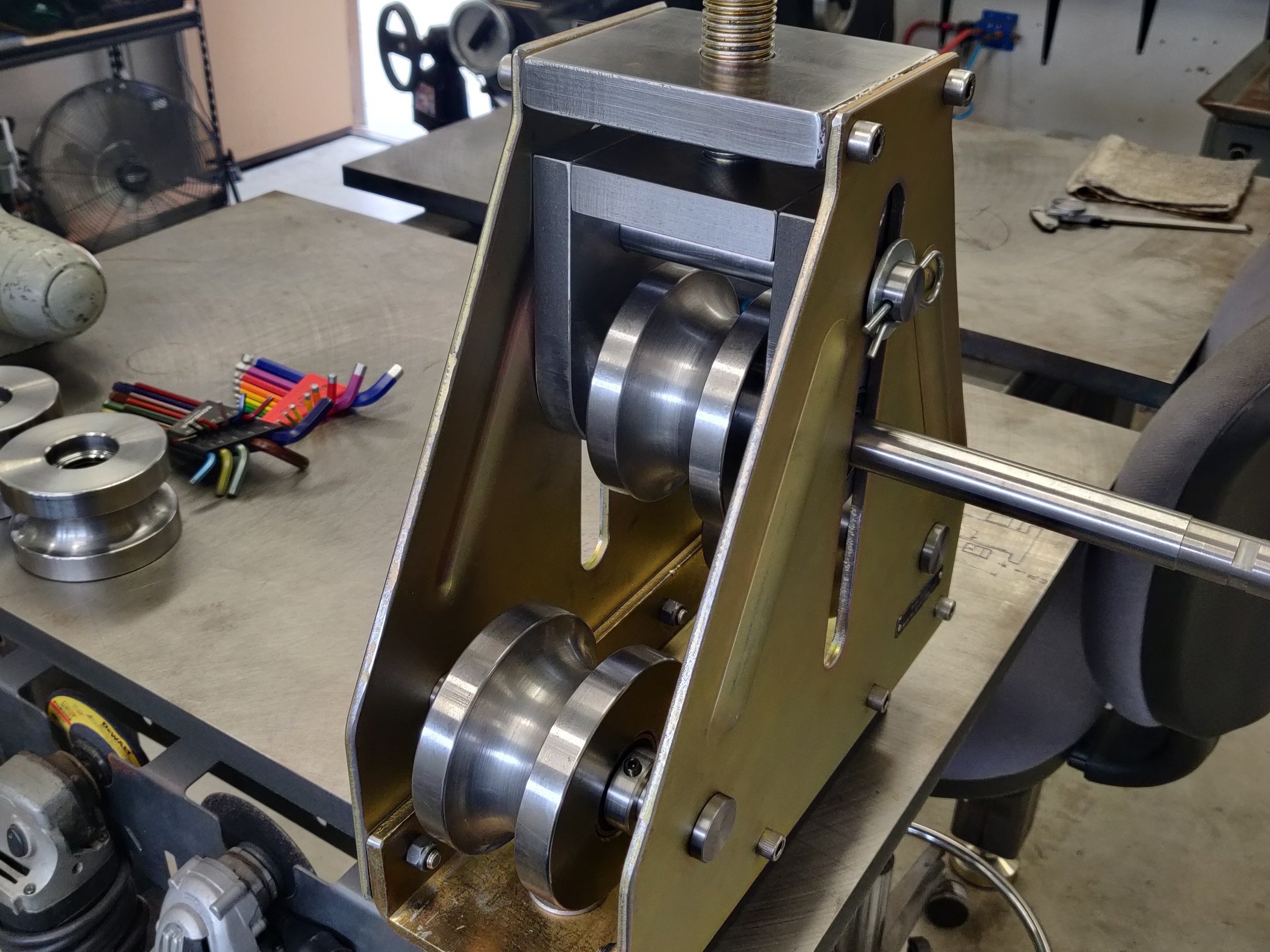

I started with what I considered the more difficult and unknown part of the project: the top of the awning which have a very shallow bend to them. I cut them to length, notched them and then began rolling them in my brand new Harbor Freight pipe bender....

Well that didn't work, lol. It turns out pipe benders, and I believe this is true for most, but even more so with super cheap ones like this, they tend to want to twist the work at the same time. That's what happened here.

I decided to remake a lot of the part of the pipe bender to help mitigate the twisting. It helped quite a bit, but didn't get rid of it all together. I ended up having to make a holding device that attached to the pipe. I had my brother keep is straight while I rolled the pipe through. I think they turned out quite nice. Relatively similar as well.

We bent the first one to our liking and used it as a template to eyeball the rest.

Next, I made some custom mounting brackets.

Four of the mounts are installed on the side of the BBQ while the other four are installed on the top.

Since I couldn't construct the awning on site, I made a wooded replica of the top of the BBQ where the awning would be mounted.

Here is the side mounted bracket. I welded it to the end of the tubing and ground and polished it down to look like one fluid piece.

Here are the top mounted brackets. Also welded to the bottom of the tubing.

All done!

Taking a trip to the powder coater and then to its final destination on top of the BBQ.

Installation complete and beautifully powder coated! The BBQ is structurally made of CMU, so we used concrete anchors for mounting. The fabric cover was installed a few weeks later.

This was made for my parents. My pops loves to BBQ!